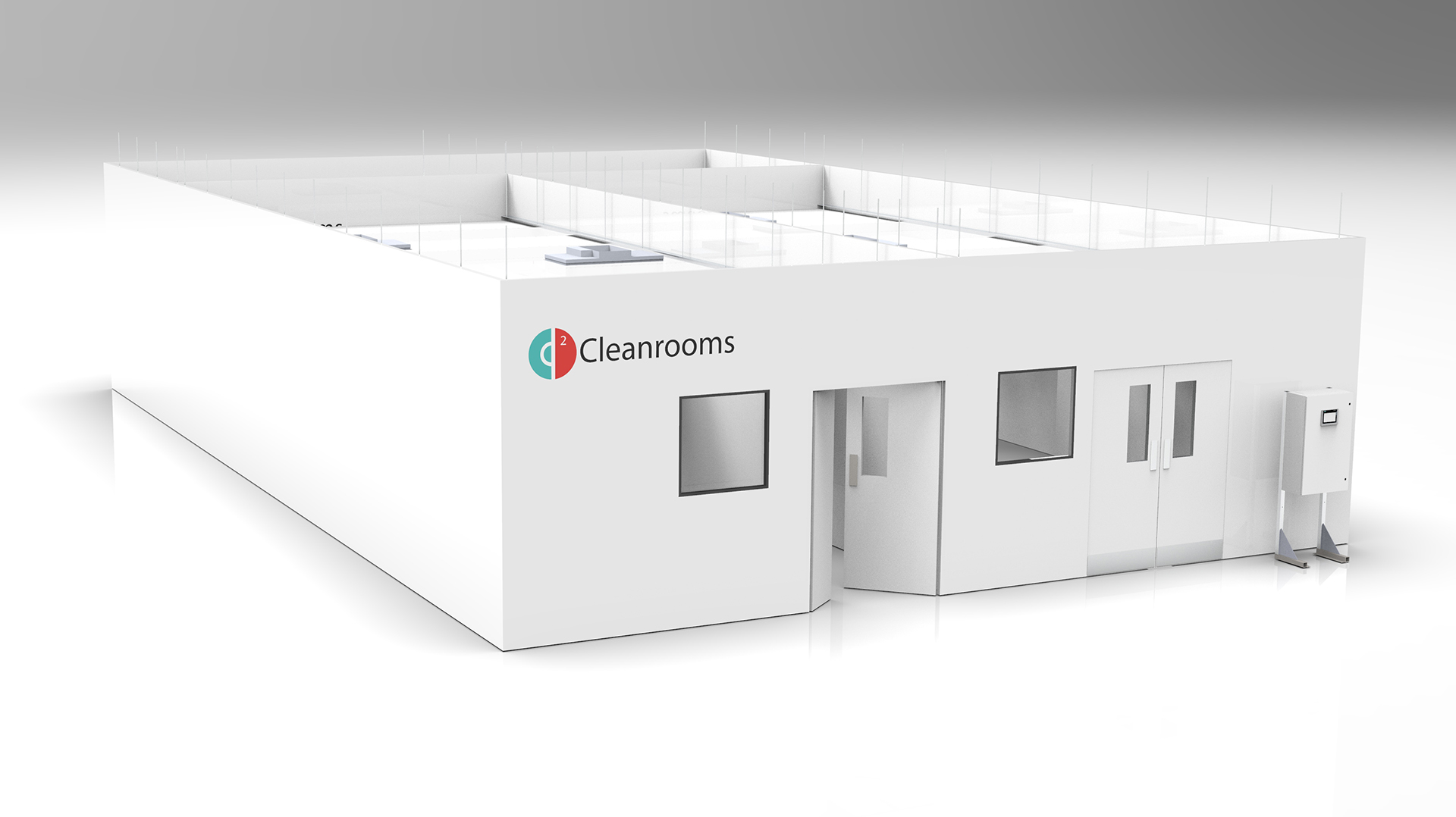

Cleanroom, Class II Lab & Dry Room for Antibody Testing Kits

Angstrom Technology was appointed to deliver critically controlled environments at sites in York and Doncaster for Covid-19 lateral flow and antibody testing facilities.

Key facts

Dry Rooms & Class II Laboratory

At sites in York and Doncaster

73.5m² dry room at Doncaster

Plus a 75.6m² class II laboratory

4 dry rooms totalling 163m² at York

Including mezzanine installation

Humidity control

Designed to achieve 10±5% RH

What did our client need?

As part of the UK-Rapid Test Consortium our client needed to scale up their production of COVID-19 lateral flow antibody testing kits. Angstrom were appointed to deliver critically controlled environments at sites in York and Doncaster. The suites were fast tracked as part of Angstrom’s commitment to supporting the fight against Coronavirus.

Although the User Requirement Specification was different for each site to accommodate individual process needs, some common elements were delivered across both sites.

The project

Our project scope at Doncaster covered both the installation of a new 73.5m² dry room and a 75.6m² class II laboratory, as well as temperature and relative humidity control upgrades to an existing laboratory.

In York, the 163m² facility we installed consists of 4 rooms with an access corridor and ante room for people and product flow.

We installed a mezzanine at York to increase the available space within the facility and house the dry room. The mez-deck features general access and utility staircases, with mid and top tier landings.

Dry Rooms & Class II Laboratory

For the dry rooms, the primary environmental requirement was to deliver humidity control to meet 10±5% RH. This was achieved by dehumidifiers in the HVAC system, using desiccant rotor technology to dry air before introducing it to the room through HEPA filtration to achieve ISO Class 9 requirements.

A level of re-circulation was achieved in each classified environment through integrated air return panels, to reduce the processing demands on the HVAC system, controlling energy consumption and running costs. Door interlock systems were also installed, creating airlocks to maintain the integrity of each controlled environment.

The envelope system supports the tight levels of control required due to the Kingspan UltraTech Versatile insulated panel’s air leakage and U-value performance.

START A PROJECT WITH US

Our design and build specialists have experience working with customers in all kinds of industries on a global scale, achieving great results time and time again. We’d love to work with you as well!

REQUEST A QUOTE